Pneumatic Presses

Grape pressing is one of the most important stages of grape processing. It is a delicate process that requires extensive knowledge and experience. In order to achieve constant wine quality, the pressing should always be adapted to grape characteristics, most importantly grape variety, ripeness degree, and the stems to grape berries ratio. Before pressing, the winemaker has to determine the kind of wine he wants to produce in terms of style (fruity, young, wine for aging, etc.) and type (sparkling wine, rosé, etc.).

That is why the pneumatic press is an indispensable device in a winery today.

Tradition and quality

Škrlj d.o.o. is a family business that has been developing grape presses based on their own experience. Being winemakers themselves, they knew exactly what needed to be done. Every product they made was tested and improved in their own winery. Today, it can be said with certainty that what Škrlj grape presses bring to the table are proven quality, long lifespan, and success for a winery.

The presses are regularly upgraded, we try to update their design and add innovations as frequently as possible, while also searching for any solutions that are better suited to enological trends and demands.

Choose a pneumatic press.

Learn more about pneumatic presses

- compact support frame (stainless steel EN 1.4301)

- drive mechanism protection cover, ABS plastic

- transport wheels: 2 fixed wheels, 2 swivel wheels with brake

- safety cord

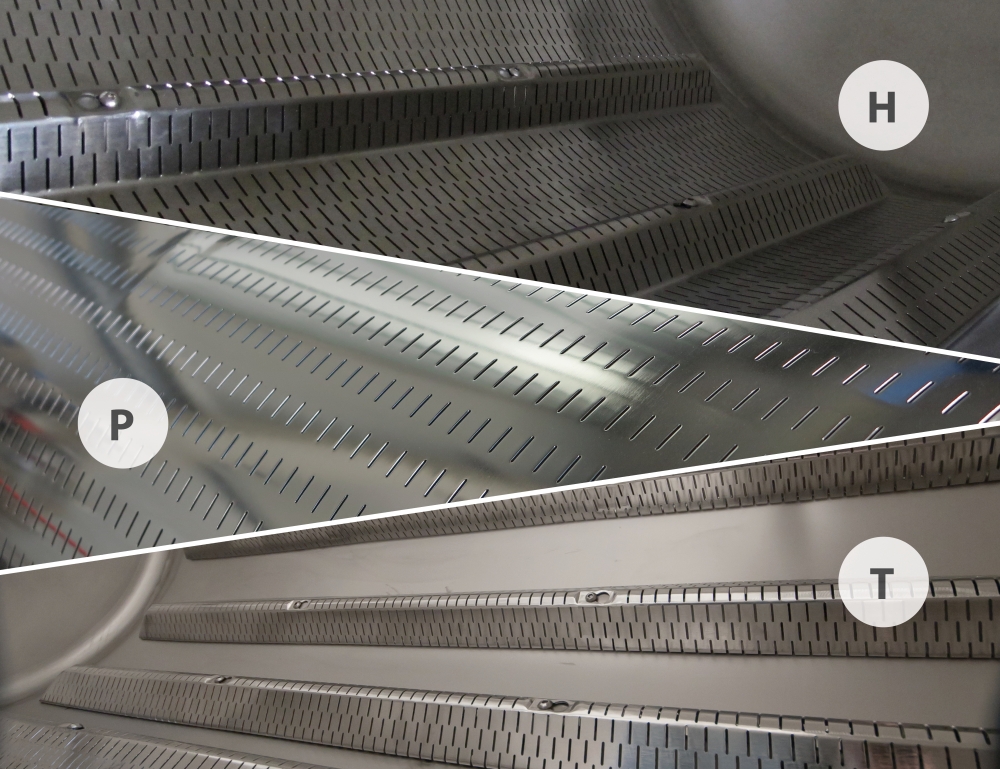

- model P: open system, perforated drum

- model T: closed system, perforated drain channels

- model H: closed system, perforated drain channels (connected), larger drainage surface

- electropolished drain channels

- cooling jacket in the cylindrical part of the drum (option)

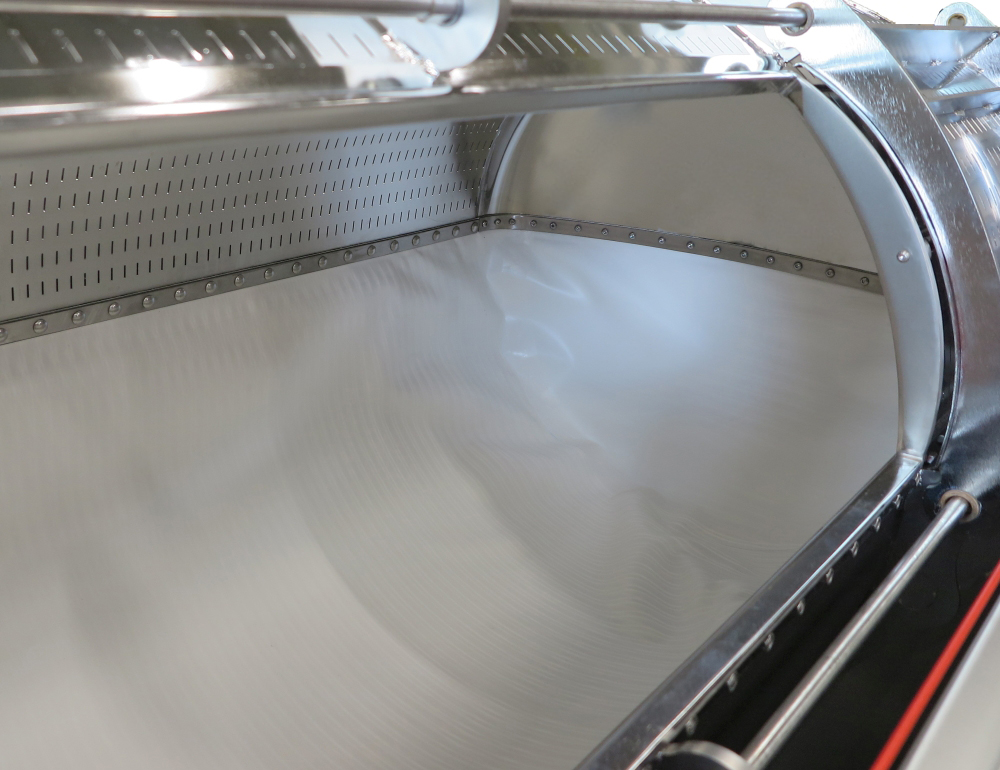

- drum cleaning opening

- covers half of the drum surface

- material: special PVC-coated fabric

- certified for use in the food industry

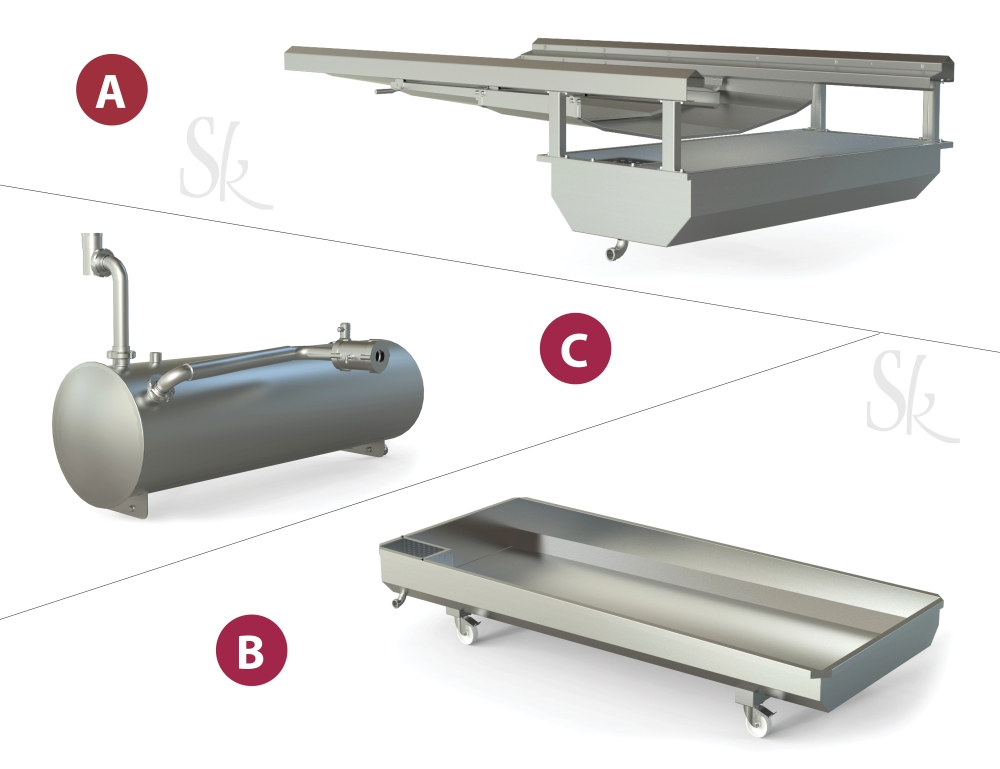

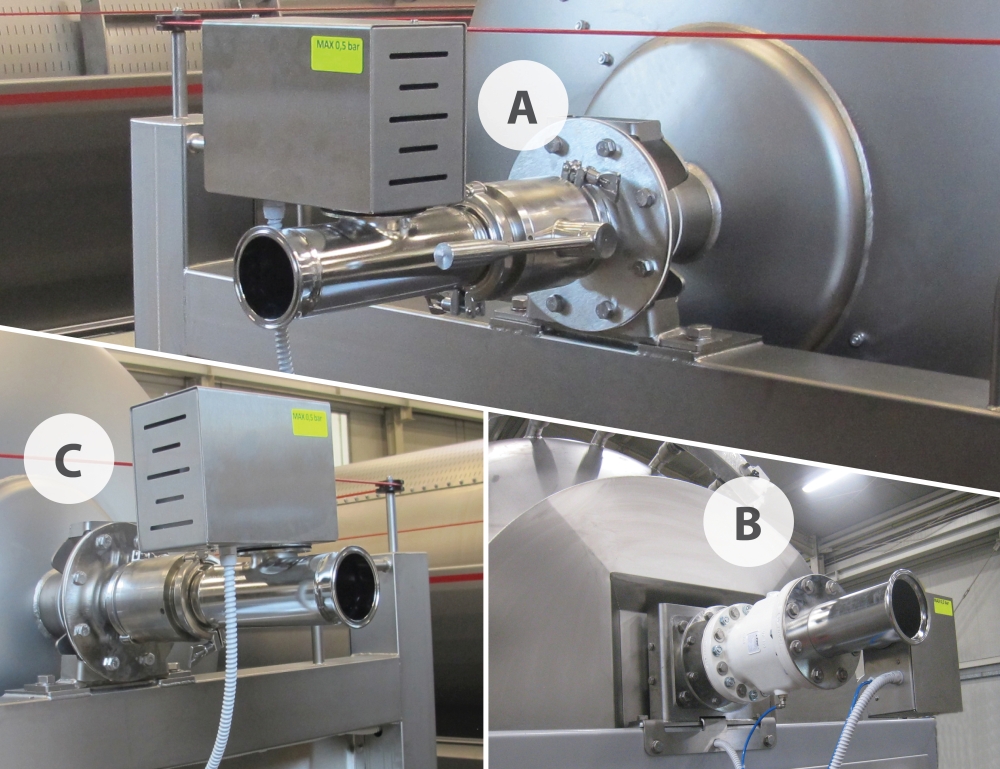

- fixed juice collection pan, movable drainage plateau (figure A)

- juice collection pan on wheels, fixed drainage plateau (figure B)

- hermetically sealed juice collection pan, only for press model PSH (figure C)

- collection pan outlet sieve

- level switch

- electrical cabinet with main IG switch

- vacuum pump

- compressor, auxiliary compressor

- electric motor

- drum drive

- safety valve

- AE automatics (5 standard pressing programs and manual operating mode)

- AV/AVk automatics (10 standard pressing programs with program parameter modification and manual operating mode)

- ABR automatics (touch screen, 10 standard pressing programs with program parameter modification, possible entry of 10 additional programs, press filling program, maceration program, and manual operating mode; remote connectivity, compatibility with the Industry 4.0 standards)

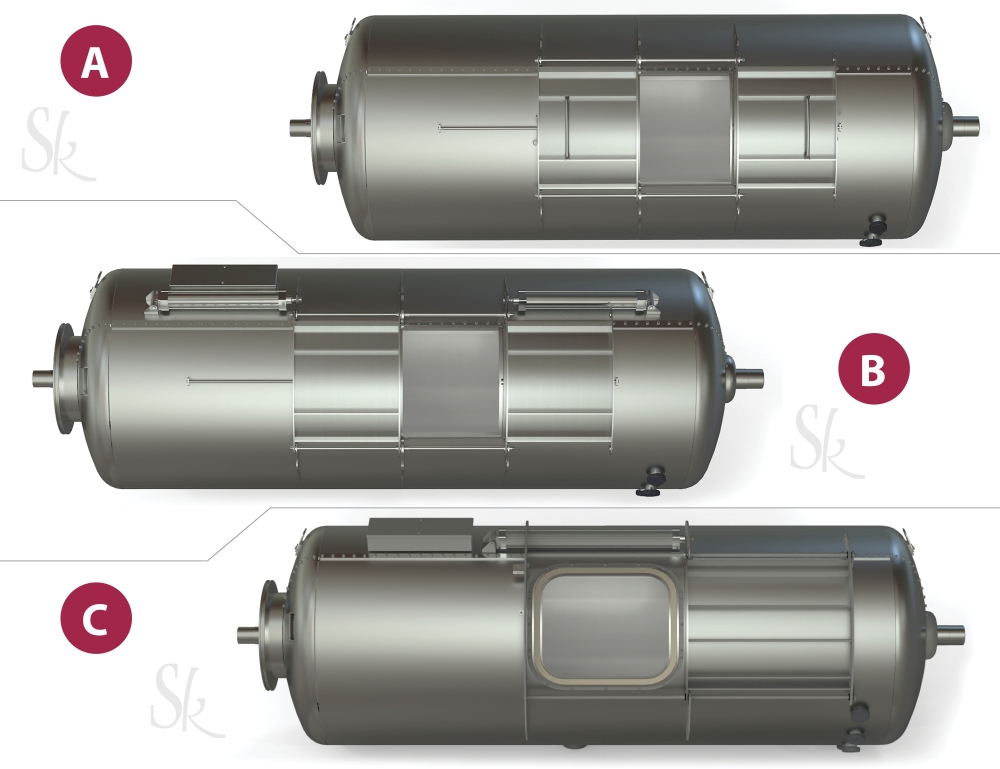

- single-leaf or double-leaf sliding door, manual opening (figure A)

- single-leaf or double-leaf sliding door, pneumatic drive on one or both door leaves, operation via the control panel (figure B)

- hermetic door, manual opening

- hermetic door, pneumatic drive, operation via the control panel (figure C)

- adjustable pneumatic door opening

- press drum filling through the central filling connector with simultaneous drum rotation

- ball valve, manual control (figure A)

- pneumatic valve, control via the control panel (figure B)

- drum overfill sound alarm unit (figure C)

Filter by shape

PSP 10 AE 400V 50HZ 3PH

- Pneumatic press type PSP - open pressing system, open drum with perforated surface

- Nominal volume [hl]: 10

- Automatics: Automatics type AE

- Supply voltage: 400V 50Hz 3PH

- Max. operating press. [barg]: 1,5

- Width D in mm: 1220

- Length L in mm: 2530

- Height Z in mm: 1540

PST 10 AE 400V 50HZ 3PH

- Pneumatic press type PST - closed pressing system, closed drum with internal drain channels

- Nominal volume [hl]: 10

- Automatics: Automatics type AE

- Supply voltage: 400V 50Hz 3PH

- Max. operating press. [barg]: 1,5

- Width D in mm: 1220

- Length L in mm: 2530

- Height Z in mm: 1540

- Model year: 2024

PST 150 ABR 400V 50HZ 3PH

- Pneumatic press type PST - closed pressing system, closed drum with internal drain channels

- Nominal volume [hl]: 150

- Automatics: Automatics type ABR

- Supply voltage: 400V 50Hz 3PH

- Max. operating press. [barg]: 1,5

- Width D in mm: 2450

- Length L in mm: 6660

- Height Z in mm: 2720

- Model year: 2024

PST 200 ABR 400V 50HZ 3PH

- Pneumatic press type PST - closed pressing system, closed drum with internal drain channels

- Nominal volume [hl]: 200

- Automatics: Automatics type ABR

- Supply voltage: 400V 50Hz 3PH

- Max. operating press. [barg]: 1,5

- Width D in mm: 2650

- Length L in mm: 7000

- Height Z in mm: 2830

- Model year: 2024

CUBE2BREW // Slovenia

Mobile Container Brewery

Together with Dematech, our distributor for the South African region, we have designed and successfully carried out a mobile container brewery project. In November 2019, the Cube2Brew mobile brewery completed its first long journey as it travelled to Nürnberg, where it was part of, or better yet, the star of our stand at the BrauBeviale, a famous international beer brewing trade fair. More...

Need some help?

Fill out the form below

We approach every project individually, with every customer's wish and need in mind. A group of experts from various fields work together to find the best solution for our investor. How can we help you? Fill out our form or call us and tell us about your plans. Together, we'll find the right answer.